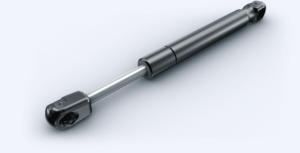

Gas springs, also known as compressed gas springs or pressurized gas springs, are devices that use compressed gas to store elastic potential energy. They are designed to provide force and damping in a variety of industrial applications. Here are some of the most common applications of gas springs in the industry:

Applications

Automotive: Gas springs are used in cars, trucks, and other vehicles for various purposes. For example, they are used in the suspension system to absorb shocks and provide a smoother ride. They are also used in the engine compartment and on the rear doors of vehicles to facilitate their opening and to keep them open.

- Furniture and Seating: In furniture and seating, such as office chairs, lounge chairs, adjustable beds, and gym equipment, gas springs are used to adjust the height, angle, or position of the elements. They provide a smooth and easy-to-use lifting mechanism.

- Medical Industry: Gas springs are widely used in medical and surgical equipment. They are used in stretchers and wheelchairs to facilitate height and position adjustments. They are also used in rehabilitation and orthopedic equipment, such as walking aids and bath chairs.

- Aerospace Industry: In the aerospace industry, gas springs are used in various applications, including aircraft doors and hatches, passenger seats, storage compartments, and cargo systems. They provide smooth and controlled opening and closing, as well as effective shock absorption.

- Industrial Machinery: Gas springs are employed in industrial machinery for various applications. They are used in machinery doors and covers to facilitate operator access and safety. They are also used in clamping and fastening devices, as well as in load lifting and handling systems.

- Laboratory and Dental Equipment: Gas springs are used in laboratory equipment, such as fume hoods and sample lifting devices. They are also used in dentist chairs and X-ray equipment, providing a smooth and secure adjustment of the patient’s position.

Distributors of Stabilus Gas Springs in Spain and Portugal: Bultz

At BULTZ, we have agreements with leading manufacturers in the market, such as STABILUS. The German company is one of the leaders in the field of gas springs. We have been working with the brand for over 20 years, always relying on them to offer the best solutions to our customers.

Additionally, we have a network of agents located in Spain and Portugal to distribute the brand’s products. You can find the different product lines of the brand on our website or on the official Stabilus website. We also have a specialized team to assist in their implementation in your company.

How Do Gas Springs Work?

Their operation is quite simple: The rod’s entry causes the gas to compress inside the spring, generating an opposing force that makes it behave like a spring. The gas inside the spring compresses or expands depending on the user’s needs.

To provide a visual example, they are present in car trunks, allowing the trunk to open smoothly, dampening the movement at all times.

There are different types of gas springs: lockable at some point in the stroke, lockable when the user requires it, non-lockable, hydraulic, and more. The wide range of features and dimensions that gas springs offer makes them highly valuable for companies in various industries.

Materials of Gas Springs and Dampers

Gas springs are composed of various elements working together to provide the desired function. The common materials used in the construction of gas springs are described below:

- Cylinder: The cylinder of the gas spring is typically made of steel or stainless steel. These materials provide strength and durability to withstand the compressed gas pressure.

- Valve: The valve is responsible for controlling the gas inlet and outlet in the spring. It is usually made of stainless steel to resist corrosion and ensure reliable operation.

- Piston: The piston or plunger is the moving component inside the cylinder, moving up or down based on gas pressure. It is generally made from steel or aluminum, as these materials offer strength and lightweight characteristics.

- Seal: Seals are used to prevent gas leaks and maintain the proper pressure within the spring. They can be made of materials such as elastomers (rubber) or polyurethane to provide effective sealing.

- Compressed Gas: The gas used in gas springs is typically nitrogen, as it is an inert gas that doesn’t readily react with other materials. Nitrogen is compressed and stored in the spring cylinder, generating the necessary potential elastic energy.

It’s important to note that the specific materials used in gas springs may vary depending on the application and design requirements. Material selection depends on factors such as required strength, durability, corrosion resistance, weight, and the usage environment.

Available in Various Forces and Sizes

The STABILUS brand offers gas springs with a wide range of sizes and forces. Gas spring manufacturers provide many product variations in their product lines to tailor them to specific cases. If your company needs technical guidance in determining the type of spring that would fit your process, BULTZ has highly experienced professionals and distributors who can assist you in selecting the most suitable one for your company.

CONTACT US

RELATED POSTS